More paint

Yep, still painting. Finished the headstock.

I took the spindle apart. I've got the cone pulley cleaned up. I found that the clutch disc inside needed replacing:

So, I ordered a sheet of clutch lining from McMaster:

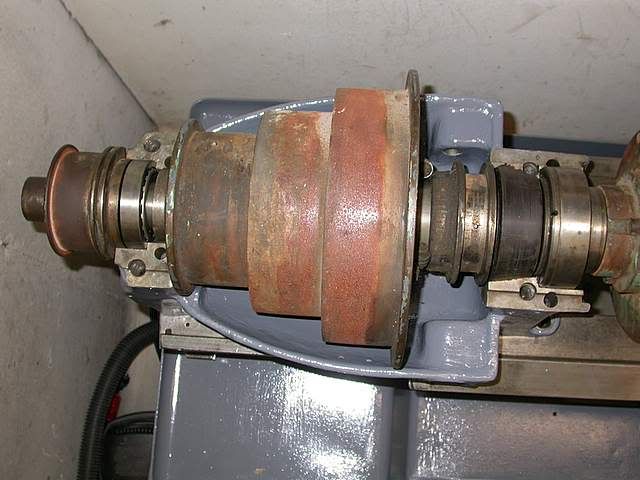

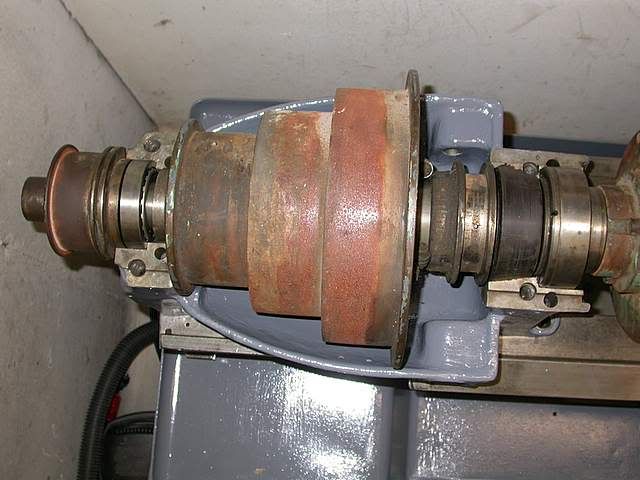

Need to cut some rings out of that, then I can reassemble the spindle (maybe). I'm thinking of possible replacing the bearings, if I was ever going to do it, now would be the time. Here's a shot of the assembled spindle (before I took it apart):

Now I'm working on painting the carriage and the motor and gearbox mount:

I really need to find a motor to use for it. My current plan is to use a timing belt to run from the gearbox to the cone pulley, and if I use that, then I can't assemble the headstock until the belt is on. But, I can't buy the belt until I have the motor so that I know what length I'll need. A flat belt wouldn't require this, but a pulley for the gearbox that would work with a flat belt isn't cheap.

I've also thought about buying a 3 phase motor, and using a VFD with that. Then I wouldn't need the gearbox. I am purchasing a horizontal milling machine that also needs a motor, and I may be able to share the VFD with that.

I took the spindle apart. I've got the cone pulley cleaned up. I found that the clutch disc inside needed replacing:

So, I ordered a sheet of clutch lining from McMaster:

Need to cut some rings out of that, then I can reassemble the spindle (maybe). I'm thinking of possible replacing the bearings, if I was ever going to do it, now would be the time. Here's a shot of the assembled spindle (before I took it apart):

Now I'm working on painting the carriage and the motor and gearbox mount:

I really need to find a motor to use for it. My current plan is to use a timing belt to run from the gearbox to the cone pulley, and if I use that, then I can't assemble the headstock until the belt is on. But, I can't buy the belt until I have the motor so that I know what length I'll need. A flat belt wouldn't require this, but a pulley for the gearbox that would work with a flat belt isn't cheap.

I've also thought about buying a 3 phase motor, and using a VFD with that. Then I wouldn't need the gearbox. I am purchasing a horizontal milling machine that also needs a motor, and I may be able to share the VFD with that.

<< Home